For all BC100 and RGC180 Clients

Preventative maintenance is the key element to avoiding downtime. Today’s blog is a reminder for those using compressors in conjunction with the BC100 Book Capture System and the DT RGC180 Capture Cradle.

Maintenance for the compressor is broken down into four segments: Weekly, Monthly, Quarterly and Yearly. Following this schedule will lessen the possibility of technical issues and keep you up and running.

Weekly

- Check the oil level in the window on the motor housing. Oil should be at the indicated level when the motor is off.

Monthly

- Drain water that has accumulated in the outlet filter. Do this with the housing under pressure. There is a button on the bottom of the housing.

- Drain water that has collected in the air tank. Attach plastic tubing to the output stem of the tap on top of the tank and place the other end in a suitable container. TAKE PRECAUTIONS AGAINST ACCIDENTAL SPRAYING OF WATER. With the tank under pressure, tip the tank slightly forward and open the valve.

- Check the integrity of all air hose and electrical connections and for screws loosening due to vibration.

- Wipe down the compressor with a soft cloth. Dust and dirt can hamper the efficiency of the compressor.

Quarterly

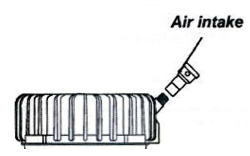

- Check the air intake filter and replace if necessary.

Yearly

- Check the filter reducer and its parts.

- Check the safety valve by pulling the ring while tank is under pressure.

- Change the oil. Use only ROLOIL-SINCOM/32E, other oils may cause damage.

- It may be necessary to disassemble motor unit from air tank.

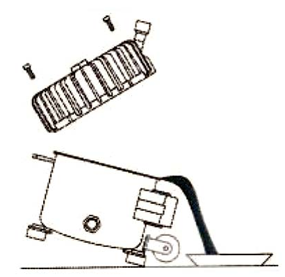

- Remove the motor cover by loosening the 4 screws.

- Tilt the motor unit toward the outlet side (Do Not Turn It Upside Down). Use your hand to keep the unit in place.

- Drain all the oil into a suitable container. Waste oil must be disposed or recycled in accordance with local regulations.

- Replace the cover on the motor unit, check the O-ring in the cover for proper seating.

- Tighten the 4 screws to secure the cover.

- Reassemble the motor unit on the air tank.

- Remove the plug from the oil fill port on top of the motor housing and refill reservoir. Oil must never be over the max fill level mark on the window in the side of the housing.

Please note that this information is also available in your compressor manual. Contact DT Tech Support if you have any questions regarding this process.